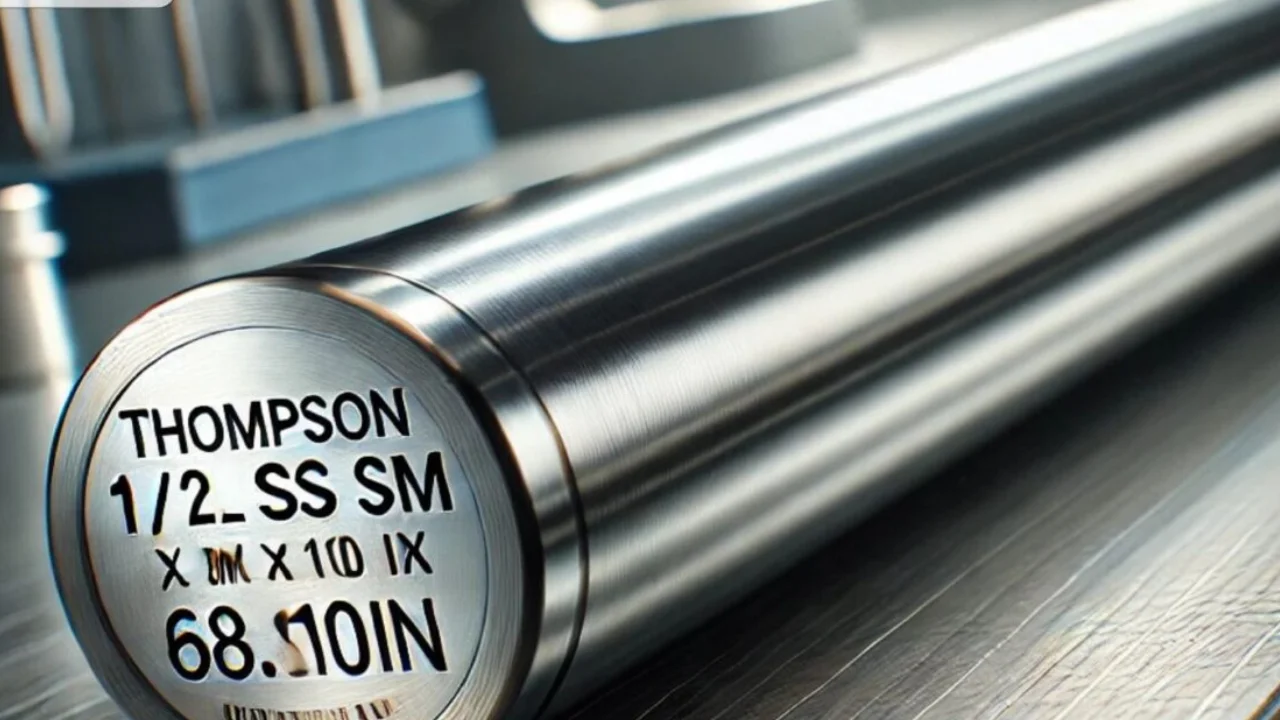

The Thompson 1 1/2 L SS SM x 68.810in is a highly regarded part known for its top-tier quality and superior engineering. As industries progress and the need for strong, dependable materials continues to rise, this component remains an essential choice for a variety of uses. Constructed from premium stainless steel, it is engineered to endure the challenges of tough environments while retaining its strength and functionality. Its robust design ensures that it continues to perform reliably, even under the most demanding conditions.

Key Features of the Thompson 1 1/2 L SS SM X 68.810in Component

Understanding the detailed specifications of the Thompson 1 1/2 L SS SM x 68.810in is crucial for evaluating its potential in various applications. Below are the key attributes of this precision-crafted rod:

- Diameter: 1 1/2 inches (38.1 mm)

- Material: Stainless Steel (SS), selected for its exceptional resistance to corrosion, wear, and impact.

- Length: 68.810 inches, providing a specific length ideal for industrial and mechanical tasks that demand extended reach.

- Surface Treatment: SM (Smooth Machined) finish, designed to reduce friction and wear, especially in high-stress conditions.

- Applications: Suitable for both low and high-temperature environments, ensuring versatility across multiple industrial sectors.

These characteristics position the Thompson 1 1/2 L SS SM x 68.810in as a reliable option for a wide range of industries, from engineering to specialized machinery and construction.

Advantages of the Thompson 1 1/2 L SS SM X 68.810in Rod

1. Superior Corrosion Resistance

One of the standout benefits of stainless steel is its strong resistance to corrosion. This makes the Thompson 1 1/2 L SS SM x 68.810in rod ideal for applications in harsh environments where exposure to moisture, chemicals, or extreme conditions is common. Industries like marine, chemical processing, and outdoor machinery benefit significantly from this durability.

2. Robust Strength and Longevity

The Thompson 1 1/2 L SS SM x 68.810in rod is designed to offer exceptional strength and resilience. Made from stainless steel, it can endure high levels of stress and impact without failure, ensuring reliable performance even under heavy loads. This makes it especially useful in demanding fields like heavy machinery and construction projects, where consistent durability is required.

3. Smooth Machined Finish (SM) for Enhanced Performance

The SM finish provides a smooth, friction-reducing surface that improves the rod’s efficiency in dynamic environments. By minimizing wear and tear on the rod and surrounding components, this finish helps prolong their lifespan and reduces the frequency of maintenance, offering a cost-effective solution for long-term use.

4. Temperature and Pressure Resistance

Stainless steel is known for its high tolerance to both extreme temperatures and pressures, and this rod is no exception. It maintains its integrity in high-heat and low-temperature conditions, making it perfect for industries that face temperature fluctuations or high-pressure environments, where other materials may not hold up as well.

5. Adaptability Across Multiple Industries

With its robust properties and precise specifications, the Thompson 1 1/2 L SS SM x 68.810in rod is suitable for a variety of industries, including automotive, aerospace, construction, and manufacturing. Its versatility ensures it can meet diverse operational needs efficiently and reliably, no matter the challenge.

Exploring the Specifications of the Thompson 1 1/2 L SS SM x 68.810in

The product code “1 1/2 L SS SM x 68.810in” reveals several important details about this component. The “1 1/2 L” refers to the nominal diameter, indicating its compatibility with a broad array of applications in fields like plumbing, manufacturing, and structural construction. The “SS” signifies that it is constructed from stainless steel, a material known for its remarkable durability and resistance to corrosion, making it ideal for long-term use in challenging environments. The “SM” marks the component’s specific design elements, which contribute to its enhanced performance, while the precise length of 68.810 inches ensures it fits seamlessly into existing systems and installations.

Broad Industry Applications

The Thompson 1 1/2 L SS SM x 68.810in is a versatile component with wide-ranging applications across various industries, including manufacturing, construction, and automotive sectors. In manufacturing, it is commonly used in the assembly of heavy-duty machinery where strength and reliability are crucial. In the construction industry, its durability and strength help ensure the safety and stability of structures. In automotive applications, it plays a key role in maintaining the performance and longevity of vehicle systems, ensuring they operate efficiently under various conditions.

A Commitment to Excellence in Quality

Choosing the Thompson 1 1/2 L SS SM x 68.810in guarantees a product built to meet the highest standards of durability and performance. Its superior engineering and high-quality materials make it an ideal solution for professionals who prioritize the longevity and reliability of their equipment. This component is an excellent choice for anyone looking to enhance the performance and durability of their operations.

In the following sections, we will explore in greater detail the specific features, applications, installation instructions, and maintenance tips for the Thompson 1 1/2 L SS SM x 68.810in, empowering users with the knowledge to make well-informed decisions and maximize its potential in their projects.

Applications of the Thompson 1 1/2 L SS SM x 68.810in in Demanding Environments

The Thompson 1 1/2 L SS SM x 68.810in is highly favored in industries where precision and reliability are essential. Its strong material properties and exact measurements make it ideal for various critical applications. Some potential uses include:

Piping Systems: In industries like chemical processing, petrochemical production, or food manufacturing, this component is valued for its durability and non-reactive qualities, ensuring a long-lasting, reliable piping solution.

Automotive Parts: The component is also often utilized in automotive systems, including fuel lines, braking systems, and exhausts, where its robustness and ability to withstand extreme weather conditions are critical for both performance and safety.

Aerospace and Defense: This rod is essential to hydraulic systems in the aerospace and defense industries, where any malfunction might have catastrophic repercussions. As a result, it is critical to employ components with outstanding integrity and performance.

These applications highlight the versatility and dependability of the Thompson 1 1/2 L SS SM x 68.810in in industries that require uncompromising quality and precision.

Installing and Maintaining the Thompson 1 1/2 L SS SM x 68.810in: A Comprehensive Guide

Installation Process

To ensure the proper setup of the Thompson 1 1/2 L SS SM x 68.810in and guarantee its effective operation, it is important to follow a systematic approach:

- Preparation: Gather the necessary tools before starting the installation. You’ll need wrenches, screwdrivers, measuring tape, and calipers. Ensure your workspace is organized and free from clutter to promote efficiency during installation.

- Site Inspection: Inspect the installation site to ensure it is clean and clear of any debris. Confirm that the surfaces where the component will be placed are stable and appropriate for securing the Thompson part.

- Measurement Accuracy: Proper measurement is key to a successful installation. Use a caliper or measuring tape to check that the dimensions of the Thompson component match your system’s requirements. This prevents any installation issues later on.

- Positioning: Place the component in its designated location, ensuring that it aligns properly with other system components. If connecting to an existing setup, double-check that all connection points are compatible and correctly positioned.

- Securing the Component: Fasten the Thompson component with suitable fasteners like bolts or brackets. Be sure to follow the manufacturer’s torque specifications carefully to avoid damaging the material, which could affect its long-term performance.

- Final Inspection: After installation, perform a thorough check to confirm that all connections are secure and that there are no alignment issues. This step is crucial to ensuring the setup is correct and ready for use.

Maintenance Guidelines

Regular maintenance is essential to prolong the life and efficiency of the Thompson 1 1/2 L SS SM x 68.810in. Follow these tips to ensure continued performance:

- Routine Inspections: Set up a maintenance schedule to regularly inspect the component for wear, corrosion, or loose connections. While stainless steel is corrosion-resistant, keeping the part clean is still important to preserve its effectiveness.

- Cleaning: Clean the surface using a mild detergent and water mixture to remove any dirt or grime buildup. Regular cleaning helps maintain optimal performance.

- Corrosion Protection: In environments that are exposed to harsh conditions such as high humidity or chemicals, consider applying a protective coating to boost the component’s resistance to corrosion and extend its lifespan.

- Addressing Common Issues: During inspections, watch for loose connections or any signs of misalignment caused by operational stresses. Promptly tighten connections or realign components to prevent further damage.

- Consulting Professionals: If significant wear or damage is noticed, it’s advisable to consult a professional for advice on whether repairs or replacements are needed. Taking a proactive approach will help save time and costs in the long run.

By following these installation and maintenance procedures, you can ensure the Thompson 1 1/2 L SS SM x 68.810in continues to perform reliably across a wide range of applications, providing excellent service for years to come.

Advancing Technology with Thompson 1 1/2 L SS SM x 68.810in Components

Integration with Modern Technological Systems

As industries continue to advance and new technologies emerge, components such as the Thompson 1 1/2 L SS SM x 68.810in are becoming increasingly integral to more sophisticated systems. From automated production lines to cutting-edge automotive technologies and next-generation aerospace designs, ensuring that existing components are compatible with evolving technologies is crucial. The Thompson 1 1/2 L SS SM x 68.810in’s superior design and material properties enable it to seamlessly integrate into these advanced systems, enhancing both performance and reliability.

Industry Influence

The contribution of the Thompson 1 1/2 L SS SM x 68.810in to various industries is profound. In the automotive sector, the reliability of such components directly affects vehicle safety and overall performance. In aerospace, the precision and strength of these parts play a critical role in ensuring the operational safety and efficiency of aircraft.

Challenges and Considerations

While the Thompson 1 1/2 L SS SM x 68.810in offers significant advantages, there are challenges associated with its use. The cost of manufacturing high-grade stainless steel and producing such precise components can be considerable. Additionally, installing and maintaining these parts requires expertise and adherence to strict industry standards to ensure optimal performance and longevity.

Why the Thompson 1 1/2 L SS SM X 68.810in is the Ideal Choice for Your Projects

When selecting components for critical applications, the Thompson 1 1/2 L SS SM X 68.810in stands out for its superior durability, reliability, and performance. Crafted from high-quality stainless steel and featuring a smooth-machined finish, this component is engineered to thrive in tough environments, making it the go-to choice for professionals in a variety of industries. Its versatility in both specialized and general industrial uses allows for optimal flexibility in design, providing a trusted solution for diverse project needs.

Premium Material for Exceptional Performance

Stainless steel is renowned for its strength, corrosion resistance, and resistance to high and low temperatures, making it the material of choice for demanding applications. The Thompson 1 1/2 L SS SM X 68.810in combines these essential properties, ensuring outstanding performance even under the most challenging conditions. Its long-lasting nature allows it to perform reliably in industries where other materials might fail.

A Smart Investment for Long-Term Benefits

While the initial cost of the Thompson 1 1/2 L SS SM X 68.810in may be higher compared to lower-grade alternatives, its durability and minimal maintenance requirements make it a cost-effective option in the long run. Reduced frequency of replacements and repairs ensures significant savings over time, making it an excellent value for industries with demanding operational conditions. This investment pays off by minimizing downtime and maximizing the component’s useful lifespan.

Read More: Exploring the Versatility of 1 1726.96-628.96

Final Words

The Thompson 1 1/2 L SS SM X 68.810in is more than just a component; it’s a testament to precision engineering and quality craftsmanship. Its high-grade stainless steel construction, exceptional durability, and versatile applications make it a trusted choice for professionals across industries. By investing in this reliable solution, you not only enhance the performance and efficiency of your projects but also ensure long-term value and peace of mind. With the right installation and maintenance practices, the Thompson 1 1/2 L SS SM X 68.810in can be a cornerstone of your success in any demanding application.

For More Information Check It Out CreativeInsider